Revolutionizing Foodtech Through Molecular Farming

)

1. From pharming to farming

Pharming is a term derived from the combination of ‘pharmaceutical’ and ‘farming.’ The concept, which began to take shape in the early 2000s, aimed to utilize genetically modified plants as bio factories for producing therapeutic recombinant proteins, spanning from antibodies to injectable enzymes for treating rare genetic diseases. The first proof-of-concept emerged in the 1990s, involving the production of human serum albumin through transgenic tobacco and potato plants. This pioneering effort aimed to address a significant challenge within the pharmaceutical industry: the high cost of therapeutics, particularly for chronic and orphan disease.

This issue persisted even after biotechnology had resolved key problems associated with the initial hormonal treatments that were already available, such as life-long insulin injections for diabetes through the engineering of human or mammalian cells. In 1923, Frederick Banting and John Macleod were jointly awarded the Nobel Prize in Medicine for their discovery that the absence of a small protein produced in the pancreas, insulin, was the cause of diabetes, and that its introduction into the bloodstream could effectively treat the disease. The pharmaceutical company Eli Lilly was the first to initiate insulin extraction and production, which involved extracting insulin from the pancreases of mammals like pigs and cows. This process was costly, dependent on the availability of source materials, and susceptible to contamination from pathogens that could be transmitted to humans.

Genetic engineering provided a solution by allowing the expression of human insulin in a simple bacterium, Escherichia coli, which eliminated the need for slaughterhouses and shifted the production to sterile GMP-compliant bio- reactors. However, not all types of protein therapeutics can be produced using bacteria like Escherichia coli. Bacteria, as prokaryotes, lack the post-translational modification of proteins, which can significantly affect the reception and therapeutic effectiveness of the proteins in the human body. For example, proteins like glucore-brosidase and alpha- galactosidase A, used to treat Gaucher disease and Fabry disease, require cells to add the necessary post-translational modifications to the amino acid sequence, ensuring proper functionality in the human body.

To address this requirement, these proteins were typically produced by genetically engineering human or mammalian cells. However, the drawback of mammalian cell culture is the high production cost, which can result in the final price of therapeutic proteins produced through these systems reaching thousands of euros per gram (and even exceeding this amount). On the other hand, plant cells can perform post translational modifications of proteins, some-what similarly (though not identically) to mammalian cells.

For these reasons, researchers began to explore the potential of using plants as bio factories to manufacture pharmaceutical therapeutics. Plants, in fact, offer several advantages over mammalian cell systems. First, they do not harbour pathogens that could pose risks to human health. Second, as eukaryotes, they can perform crucial post-translational modifications. Third, they do not require expensive bioreactors or growth media, such as calf serum, making scalability a more feasible prospect by adjusting the amount of land used. This vision of the early 2000s ignited excitement and optimism around molecular pharming as the future production system for therapeutic proteins, including antibodies, recombinant enzymes, human and veterinary vaccines, and more (1).

In pursuit of this vision, the European Union embarked on an ambitious international project in this field called Pharma-Planta, which brought together scientists from 12 countries, including South Africa (2). However, within a few years, it became evident that major pharmaceutical companies weren't particularly interested in the cost-effectiveness of plant-based pharmaceutical production. This was because the primary expenses in drug development were associated with clinical trials. Additionally, regulatory barriers emerged, emphasizing the absence of a clear regulatory framework to ensure the safe introduction of plant- based pharmaceuticals into the market. The reluctance to transition from traditional methods to an unproven and unregulated technology partly accounts for why molecular pharming has remained a niche platform over the past two decades.

Moreover, the initial enthusiasm surrounding this new technology faced significant setbacks when it was revealed that genetically modified corn plants, created by the biotech company ProdiGene Inc., had mixed with a subsequent soybean crop in Nebraska. This incident prompted the U.S. Department of Agriculture (USDA) to fine the company and require them to purchase and destroy the contaminated soybeans. This controversy sparked a heated debate, with farmers and activists voicing their concerns and objections to the use of engineered plants for pharmaceutical production (3).

The Resurgence of Molecular Pharming

Despite these earlier challenges, the outbreaks of Ebola in 2014 and COVID-19 in 2020 thrust this technology back into the spotlight. Its remarkable scalability, unburdened by the limitations of bioreactors, emerged as a potential solution to the global demand for vaccines. In 2014, researchers from the biotech company Mapp Biopharmaceuticals successfully produced ZMapp4, a cocktail of virus-neutralizing antibodies directed against three glycoprotein epitopes of the Ebola virus. These antibodies were manufactured using Australian tobacco plants (Nicotiana benthamiana) cultivated in dedicated greenhouses.

Although ZMapp’s clinical trials did not yield the desired results, they did shed light on the incredible potential of plant-based drug production for high-output and rapid scalability (4). On the other hand, the emergence of COVID-19 in 2020 has reignited interest in innovative vaccine production methods, reviving the concept of molecular pharming as a technology with significant scalability. This resurgence has sparked discussions about the possibility of implementing on-site vaccine production in regions where the need is most pressing.

Back to the “F”: the Evolution of Molecular Farming

In contemporary times, the concept of molecular pharming is undergoing a transition from its original purpose of using genetically modified plants for therapeutic production to a new paradigm: generating functional ingredients for human and animal nutrition directly from engineered plants. This shift brings pharming back to the fields, with the aim of consistently enhancing agriculture and the food industry. Consequently, this area of biotechnology is returning to its roots, represented by the initial “F” in farming and, of course, food.

Genetically modified crops hold the potential to replace entire industrial sectors currently reliant on the exploitation of natural resources or unsustainable technologies. Many of the advantages observed in pharmaceutical production in plants, such as reduced production costs, enhanced scalability, and quicker market response that plague the pharmaceutical industry, can be extended to this new context. Furthermore, this approach offers increased sustainability and reduced environmental impact, harnessing the extraordinary chemical production capabilities of the most efficient systems on Earth: plants (5).

2. Molecular Farming: Different Approaches, Same MomentumOne term, multiple technologies

To make plants produce the same proteins as various organisms, different technologies and methods are required. Genetic transformation of plants can be either stable or transient, depending on whether the introduced genetic material is inherited by subsequent plant generations. This transformation can occur at the nucleus level or the chloroplast level and may be virus-induced or achieved through genetic modification. Let’s delve into these methods in more detail.

Transient Transformation

In this scenario, the foreign gene(s) is not permanently integrated into the plant’s genome, preventing it from being passed on to the next generation upon reproduction. The advantage is that transient transformation can produce the desired molecules relatively quickly, typically within 1–8 weeks, depending on the plant species. This technique can be used to test whether the gene functions as intended before undertaking a stable transformation of the plant’s genome.

Stable Transformation

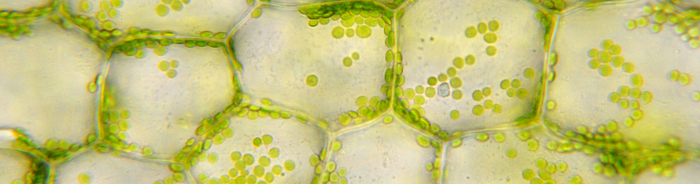

In stable transformation, the new genetic material is introduced into the plant’s nuclear DNA, becoming a permanent part of its genetic makeup, which is sub- sequently inherited by future generations. Similarly, stable transformation can be achieved by genetically manipulating chloroplasts, the small, organized structures in plant cells responsible for photosynthesis, which possess their own DNA. In this case, foreign DNA is introduced into the chloroplasts, becoming a permanent component of the plant’s genetics, which can be passed on to subsequent generations. This method is sometimes preferred over modifying the nuclear plant DNA because it involves less complex procedures and results in more stable gene expression.

GMO vs. Virus-Induced

Viruses can be utilized to introduce foreign genes into plants and express relevant proteins. This technique does not lead to a permanent modification of the plant’s DNA, which is why it is known as virus-mediated expression of proteins in non-GMO plants.

Production Systems

Open Field

Open field agriculture is the traditional method of farming and can be applied to suitable crops, such as tobacco, corn, and soy, where stable genetic transformation is feasible. While it relies on existing farming infrastructure and has relatively low capital expenditure (CAPEX), it comes with regulatory risks associated with open-field cultivation of GMOs. It also allows flexibility in production to meet demand.

Greenhouses

Greenhouse farming is suitable for non-open field crops, particularly vegetables like lettuce, tomatoes, hops, and even tobacco. Greenhouses can also be used for transiently transformed plants. They offer a partially controlled environment, enabling better control of plant nutrition and atmospheric conditions through CO2 injection. However, they are still subject to seasonality, and open greenhouses do not provide containment for GMOs.

Vertical Farming

Vertical farming is an evolution of greenhouse farming, involving indoor cultivation under fully controlled conditions, including lighting and atmosphere. These environments are contained by design, making them suitable for GMO containment.

Plants are typically grown on shelves, each illuminated by artificial lights to provide consistent inputs for growth throughout the year. Vertical farming is ideal for transient expression systems and allows for precise productivity measurement. Specific stress or signal induction for heterologous proteins, such as optogenetics tools, is more feasible in such systems. However, the limited space per plant may not accommodate larger tobacco cultivars, and the high CAPEX and OPEX make it more suitable for high-value products like pharmaceutical proteins.

Downstream Processing

One of the primary challenges hindering the adoption of molecular farming is downstream processing. Although biomass production can be more scalable and cost-effective than bioreactors, downstream processing complexity and inefficiency can negate these advantages.

This is particularly relevant for pharmaceutical-grade proteins, which require expensive purification systems like high-affinity columns when the protein is randomly expressed in the cell’s cytoplasm alongside millions or billions of other proteins.

To mitigate downstream processing costs and complexity, two strategies can be employed. First, protein purification requirements can be reduced, particularly when purity isn’t critical, as is the case in some food applications. This approach involves using different and less expensive purification systems, like isoelectric precipitation through wet separation.

The second strategy involves expressing the protein of interest in a less crowded cellular environment, such as vacuoles. These two strategies can be combined. For instance, some of the first strategies involved expressing heterologous proteins in the seed oil bodies of Brassica napus by fusing the protein with an oleosin (6). This approach can capitalize on existing industrial processes, like oil production from oilseeds, resulting in protein-rich by-products like defatted meal. Furthermore, protein content can be increased through wet separation and the use of membranes, which is a less costly alternative to high-affinity columns, although it may come with a trade-off in protein purity.

Why now?

The increasing global population, predicted to reach 10 billion by 2050, is driving a surge in meat demand. To address this growing demand sustainably, new ingredients and technologies are required. The current food system is a significant contributor to global greenhouse gas emissions, accounting for 26% of the total. Animal agriculture alone is responsible for 15% of these emissions. Most of the increased meat demand comes from emerging middle-income countries, where improved well-being has led to higher meat consumption. In response, innovations, and technologies such as alternative proteins, biomass and precision fermentation, and cellular agriculture have been considered as potential solutions to meet future protein demands (7).

Even the seemingly distant field of cellular agriculture, involving the cultivation of real meat in a lab setting, could benefit from the development of plant molecular farming. One of the hurdles in cellular agriculture is the growth media, and essential animal proteins used in the growth media could be replaced by their heterologous counterparts produced in plants.

According to the Good Food Institute (8), there are at least 12 companies currently engaged in plant molecular farming to produce alternative food ingredients. We at Grey Silo Ventures have identified 18, differing from each other in terms of molecular output (chemical compound), production process and geographic focus.

This technology is now in the spotlight as it promises to be more cost-effective compared to existing technologies. It reduces the need for expensive bioreactors and eliminates the use of transgenic animals. Additionally, when GMO containment is necessary, the use of vertical farming can optimize production space.

The shift in focus from pharmaceutical proteins to food and industrial proteins is likely to allow for the use of less expensive protein purification systems. In this context, the purity of the protein itself is less critical than with pharmaceutical counterparts. Furthermore, the growing demand for plant proteins is paving the way for multi-level production systems. In these systems, most of the proteins are recovered to create a food protein concentrate or isolate, while the heterologous protein can be further separated from the process as a pure fraction. This potential separation allows for a more economically viable process (9,10).

Investors are closely monitoring plant molecular farming as a cutting-edge avenue for fostering innovation within the alternative protein sector. This approach enables the cost-effective production of high-value functional ingredients. In 2021, investments in this field experienced a notable surge, reaching a total of $118 million across 8 deals.

According to GFI, Moolec Science made history in early 2023 as the pioneer publicly traded company specializing in plant molecular farming, joining the select group of publicly traded alternative protein firms. Moolec Science acquired LightJump Acquisition Corporation, a publicly traded special purpose acquisition company (SPAC), through a reverse merger valued at $138 million.

Subsequently, the amalgamated entity commenced trading on the NASDAQ under the ticker symbols MLEC and MLECW from January 3, 2023. As part of this transaction, the company secured $10 million in development capital from undisclosed investors on the same date through a private placement.

3. How many applications?

Given the extensive range of potential applications across various segments in both the pharmaceutical and food markets, the Molecular Farming total addressable market is extraordinarily vast. In addition to the well-known applications in the pharmaceutical industry, such as antibodies, vaccines, and medical proteins, plant molecular farming technology has made inroads into the food industry in recent years.

Several startup companies are now exploring this field to produce food and industrial proteins, which hold significant market potential. There’s a strong focus on various alternative proteins like dairy proteins (casein and whey), enzymes, heme (a crucial ingredient in plant-based burgers like those from Impossible Meat, replicating the effect of meat-blood), collagen, and egg proteins.

Another promising area is the molecular farming production of growth factors for cultivated meat. This innovation not only has the potential to reduce their impact on pricing but also addresses ethical concerns related to the animal origin of current solutions. Furthermore, other markets that stand to benefit from plant molecular farming encompass pigments, dyes, emulsifiers, fats, and metabolites.

As a general observation, molecular farming unveils unexplored and extensive opportunities within the broader market of nutraceuticals and functional foods.